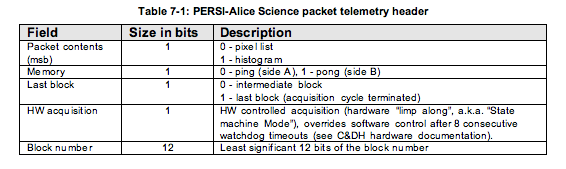

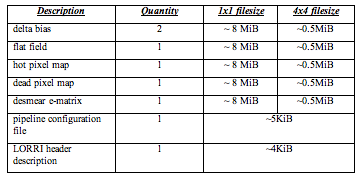

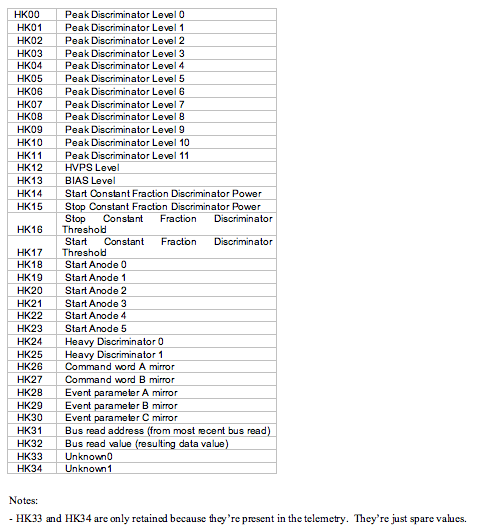

Table 7-1

Table 7-1

Table 7-1 The contents of the remainder of the data frames (the 32767-word data block) depend on the acquisition mode: - Pixel List: Each word in the data block from a pixel list exposure describes a photon event or a time hack. Photon events are indicated by bit 15 having a value of zero and time hacks are indicated by bit 15 having a value of one. For a photon event, the remaining 15 data bits encode the location of the detected event consisting of a 10-bit encoded spectral location (X) and a 5-bit encoded spatial location (Y). The time hack is used to provide temporal information about the photon events. The acquisition hardware will generate and insert time hacks in the frame on a periodic basis; the frequency of the time hacks is configurable (by command) for each acquisition in a range of 4 - 512 ms. For a time hack, the remaining 15 bits contain an incrementing counter that counts the number of 4 ms periods. This value allows for verification and correction of timing in case of lost frames or packets. - Histogram: Each word in the data block from a histogram exposure is a 16-bit "counter" giving the number of photon events detected at each specific X,Y location on the detector. The format of the detector is 1024x32 pixels, which are the spectral and spatial dimensions respectively, i.e., there are 1024 spectral elements along the X-axis and 32 spatial elements along the Y-axis, giving a total of 32768 values (however, the first word always contains the header word). The counters are stored row-wise, corresponding to the spectral dimension indexing most quickly. These counters saturate at a maximum value of 65535 to indicate a completely filled counting bin, meaning that the counters do not wrap around. In addition some special data words (header cross-identification and pulse height distribution) are overlying the lower left-hand corner of the actual array in a block of 4 (spatial) x 32 (spectral) words. This usage doesn't affect the science data contents because detector events do not occur in this region. In this over-written block, the first row contains the header cross-identification word, the second and third rows contain the 64 words of pulse height information, and the fourth row is filled with zeros. A "pulse height" is the amplitude of a photon event, and this pulse height distribution (PHD) shows the number of events in a 64-bin distribution with 6-bit resolution; the value in each PHD bin gives the number of events that occurred with the particular amplitude associated with that bin. These PHD counters also saturate at a value of 65535. So a single photon event is counted both in the spectral/spatial array and in the pulse height list. The PHD is used as a diagnostic for the health and behavior of the detector. For test purposes the instrument can fill the memory with known deterministic patterns so the interfaces to the spacecraft and ground can be verified. The instrument software allows for the generation of 5 different test patterns. 7.2.1.1 Histogram FITS file: The primary data unit in the FITS file is a 2-D raw histogram frame (also referred to as an "image") consisting of 1024x32 16-bit integer numbers. Note that the Alice instrument data are unsigned 16-bit integers (giving values of 0 to 65535). The first data extension in the FITS file contains the 64-element pulse height distribution (PHD) that was acquired together with the histogram. When the Level 1 pipeline saves the PHD to this extension, it then zeros out that part of the histogram array. The second data extension contains a 141 column by t row binary table, where t is the time of the exposure in seconds, of housekeeping values recorded during the observation (the housekeeping report rate is 1 Hz). FITS File Storage Location Description Primary Data Unit (PDU) Raw Histogram image (uncorrected counts) Extension #1 Pulse Height Distribution (PHD) Extension #2 Binary Housekeeping Table 7.2.1.2 Pixel list FITS file: Upon receiving a pixel list frame, the Level 1 processing creates a ground-calculated "reconstructed histogram" from the received pixel list data and places it in the primary data unit of the FITS file; this enables an easy quick-look inspection of the pixel list data (e.g., using most FITS viewers that by default typically display the data in the primary data unit). The pixel list data itself can be hard to interpret, so this reconstructed histogram image is desirable to enable the scientist to determine, e.g., data quality, whether the target was in the field of view, etc... The first data extension contains the raw pixel list data set, which includes the full stream of photon events and time hacks. The second extension contains the count rate derived from the pixels list data. Each count rate bin shows the number of events that occurred between successive time hacks. The resolution of this count rate data set is determined by the hack rate used for the pixel list acquisition. The length of this vector is variable depending on the source flux and the hack rate. The third data extension contains a 141 column by t row binary table, where t is the time of the exposure in seconds, of housekeeping values recorded during the observation. FITS File Storage Location Description Primary Data Unit (PDU) Reconstructed Histogram image (uncalibrated counts) Extension #1 7.2.1.3 raw pixel list Extension #2 7.2.1.4 Count rate vector from pixel list data (sampled at time hack rate) Extension #3 Binary Housekeeping Table 7.2.2 Data Sources (High/Low Speed, CCSDS, ITF) 7.2.2 Data Sources (High/Low Speed, CCSDS, ITF) PERSI-Alice data are transferred via CCSDS packets that are packetized 7.2.by the spacecraft from the Solid State Recorder. The spacecraft will packetize the PERSI-Alice High Speed Telemetry data into CCSDS packages before sending the data to the ground. Different APIDs are used to distinguish the histogram and pixel list data packets (see Table 7-2). For the PERSI-Alice science frames the spacecraft will either use the "RAW" packetized format or the loss-less compressed format to transfer the data. In either case the result will be data encoded in CCSDS telemetry packets. The package APIDs listed in Table 7-2 are used to distinguish the different Alice CCSDS packets. The packet time as listed in the CCSDS packet represents the time at which the packetization operation was performed. The second time field contains the frame collection time as sent from a spacecraft perspective, meaning this represents the time at which the spacecraft received the frame from the instrument. As the instrument immediately sends the frame at the completion of the acquisition this corresponds to the time at which the acquisition was completed.

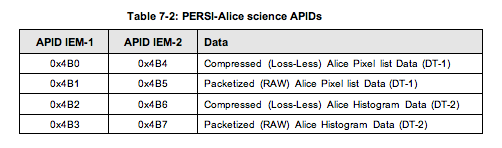

Table 7-2

Table 7-2

Table 7-2: PERSI-Alice science APIDs Packetized "RAW" telemetry: The nominal data transfer method for the Alice pixel list science data is packetized "raw" data. Each CCSDS science packet can transfer a segment of up to 480 data bytes. In order to transfer a full PERSI-Alice frame of 32768 words (16-bits), 137 science packets are needed; the first 136 packets will all be full size segments of 480 bytes, the last packet will transfer the remaining 256 bytes. The grouping flags of the packets indicate the start and end segment within a complete frame transfer. Note the '#' marks in the following tables refer to the third digit of the APID, the valid digits for these numbers are indicated in Table 7-2.

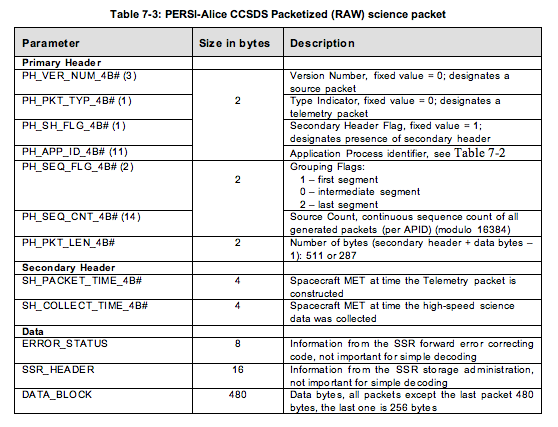

Table 7-3

Table 7-3

Table 7-3: PERSI-Alice CCSDS Packetized (RAW) science packet Lossless Compressed telemetry: The nominal data transfer method for the Alice histogram science data is lossless compressed data. When applied to pixel list data, the 'FAST' algorithm results in negligible compression rates, and occasionally in a 1% expansion, therefore lossless compression will generally not be used with pixel list data. The spacecraft uses the so called 'FAST' algorithm to compress the image data. The 'FAST' algorithm uses one-dimensional correlation between successive data elements to remove redundancy. Data is encoded in blocks of 16 successive science values, the first value of such a block is send in full 16 bits, the remainder of the block is encoded using successive differences, using an adaptive coding mechanism.

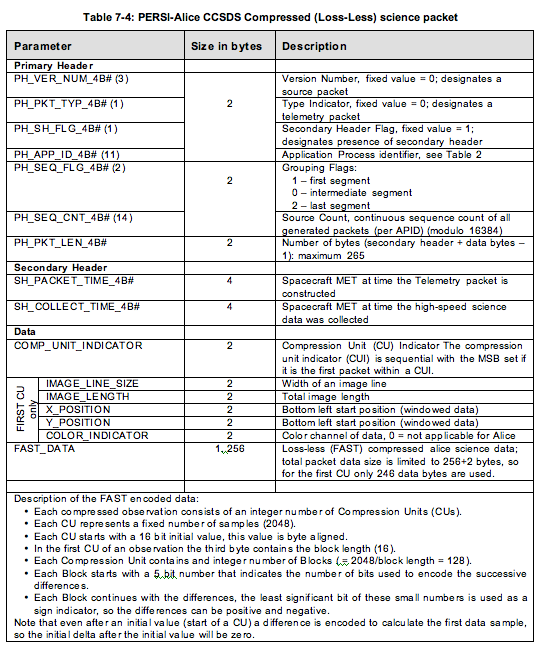

Table 7-4

Table 7-4

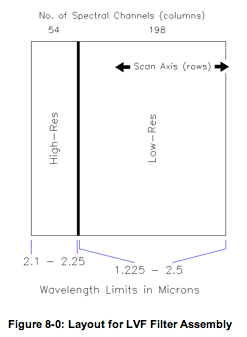

Table 7-4: PERSI-Alice CCSDS Compressed (Loss-Less) science packet 7.2.3 Definition of an "Observation" An observation will be a single histogram image or one frame of a pixel list series. Each observation will be written to a separate FITS file. A pixel list resulting from a single exposure command may therefore produce many such frames, each of which will be saved as a separate FITS file. 7.2.4 S/C Housekeeping Needed in Level 1 Files (for Calibration) Spacecraft housekeeping that may be needed in the Alice pipeline include any temperature sensors on the spacecraft around the Alice instrument and the spacecraft-measured instrument bus voltage and power consumption on the different busses. Spacecraft measured temperatures related to Alice (ApId 0x00D and 0x08D): T_A.CDH_TEMP_ALICE_BRACK_BASE_00D T_A.CDH_TEMP_ALICE_1_00D T_A.CDH_TEMP_ALICE_2_00D PDU parameters related to Alice (ApId 0x009, 0x00a, 0x089 and 0x08a): ALICE_LVPS_A_VOLT_009 ALICE_LVPS_A_CURR_009 ALICE_LVPS_B_VOLT_009 ALICE_LVPS_B_CURR_009 ALICE_ACT_A_VOLT_00A ALICE_ACT_A_CURR_00A ALICE_ACT_B_VOLT_009 ALICE_ACT_B_CURR_009 Note that these temperatures currently are not used in the pipeline processing, but may be used in the future as the code and calibrations are revised. 7.3 "Calibrated" Data Specifics "Calibrated" data as used here refers to CODMAC level 3 data. 7.3.1 Algorithm for Pipeline Overview: The Alice calibration pipeline that is run at the SOC applies various calibrations to raw Alice data to convert the data from units of counts to flux units (photons/s/cm2). Four types of operations can be performed. They are, in order of application to the data: deadtime correction, dark correction, effective area correction, and flat field correction. These are described in more detail below. 7.3.1.1 Deadtime Correction The Alice detector electronics require a finite time to process a photoelectron pulse. As a result, if photoelectron pulses arrive too close together in time, the latter pulse(s) will not be recorded, resulting in an effective decrease in the sensitivity of the instrument that is a function of the count rate. The deadtime correction time constant is 18 microseconds. At input rates below 50 kHz, the detector electronics is non-paralyzable (fixed deadtime per event that is not re-triggerable). To calculate the detector output count rate, the following formula is used: C_out = C_in / (1 + C_in tau), where Cout is the output (i.e., detected) count rate and C_in is the input count rate. At a count rate of 1 kHz, the deadtime correction factor (tau) is approximately 1.02, while at 20 kHz, the deadtime correction factor is approximately 1.56. 7.3.1.2 Dark Correction The Alice detector electronics register photon events even when the aperture door is closed and the detector is not illuminated. The spatial distribution of dark counts is approximately uniform across the detector. However, there is some low-level 2-D structure to the dark counts. Alice observations made with the aperture door closed are summed together to create a "superdark". This superdark image is then scaled to the exposure time of an Alice science observation and subtracted from the data. During in-flight commissioning, these dark counts were measured at a rate of approximately 94 Hz across the entire detector. The primary source of dark counts is the spacecraft RTG. Dark exposures are made throughout the mission to monitor the background event rate and detector performance. 7.3.1.3 Effective Area The sensitivity of Alice to UV photons varies as a function of wavelength. It is convenient to think of the Alice sensitivity in terms of the effective area of the instrument. For a point source located at infinity, effective area is defined as the area of the surface that intercepts incident photons at the same rate as is detected by the Alice instrument. Dividing the observed count rate by the effective area yields the incident flux of photons. In general, effective area depends on the geometric size of the instrument aperture, reflectivities of the optical surfaces, sensitivity and quantum efficiency of the detector, etc. The Alice effective area curve (v003) is based on pre-flight estimates and calibration stars observed by both Alice and the IUE satellite. Above 1350 Angstroms, the effective area is derived from matching the stellar flux observed by Alice with that observed by IUE. Below 1350 Angstroms, the pre-flight effective area estimate has been scaled by a factor of 0.6 so that the long wavelength end of the pre-flight effective area estimate approximately matches the calibration derived from the stellar observations. 7.3.1.4 Flat Field When uniformly illuminated by a monochromatic source, the counts detected by the Alice instrument vary from pixel to pixel with a standard deviation of approximately 15%. This spatial variation in instrument sensitivity is the instrument flat field response. As of September 2007, no suitable observations have been made from which to derive an in-flight flat field calibration. Thus the flat field correction is currently disabled in the Alice pipeline code. Current plans are that during annual checkouts, a stellar scan along the slit could be used to generate a pseudo-flat field that could be used in the Alice pipeline. 7.3.2 Format of Calibrated Data 7.3.2.1 Histogram The primary data unit in the FITS file is a 2-D calibrated histogram frame consisting of 1024x32 array of 32-bit floating-point numbers. The units of the histogram image are photons/s/cm2. The first data extension in the FITS file is a 1024x32 array of 32-bit floating numbers containing the uncertainty in the histogram image. The second data extension is a 1024x32 element array containing the wavelength for each pixel in the histogram image. The third data extension is the 64-element PHD, identical to that in the raw data. The fourth data extension is an array containing the number of photon events per second, sampled at a rate of 1 Hz. The fifth data extension is the 141 column by t row housekeeping row as in the raw data. FITS File Storage Location Description Primary Data Unit (PDU) Calibrated Histogram image (photons/sec/cm2) Extension #1 Uncertainties in histogram data values Extension #2 Wavelength Image (Angstroms) Extension #3 Pulse Height Distribution (PHD) Extension #4 Count rate vector from HK (sampled at 1 Hz) Extension #5 Binary Housekeeping Table 7.3.2.2 Pixel List The primary data unit in the FITS file is a 2-D calibrated reconstructed histogram image consisting of a 1024x32 array of 32-bit floating-point numbers. The units of the histogram image are photons/s/cm2. The first data extension in the FITS file is a 1024x32 array of 32-bit floating numbers containing the uncertainty in the reconstructed histogram image. The second data extension is a 1024x32 element array containing the wavelength for each pixel in the reconstructed histogram image. The third data extension contains a binary table of 5 columns and rows for each photon event. The five columns are the X (spectral) position of each photon event, the Y (spatial) position of the photon event, the wavelength of the photon event, the cumulative number of elapsed time intervals (starting from 0 at the beginning of the file), and the ephemeris time (et), i.e. seconds past J2000, at the time of detection. The fourth data extension is the count rate derived from the pixels list data, showing the number of events that occurred between successive time hacks. The resolution of this count rate data set is determined by the hack rate used for the pixel list acquisition. The length of this vector is variable depending on the source flux and the hack rate. The fifth data extension contains the binary housekeeping table. FITS File Storage Location Description Primary Data Unit (PDU) Reconstructed Calibrated Histogram image (photons/sec/cm2) Extension #1 Uncertainties in reconstructed histogram data values Extension #2 Wavelength Image (Angstroms) Extension #3 Binary Pixel List Table (X, Y, wavelength, time hack #, MET) Extension #4 Count rate vector from pixel list data (sampled at time hack rate) Extension #5 Binary Housekeeping Table 7.3.3 7.3.3 Scientific Units For Histogram, units are counts (histogram), angstroms (wavelength array), and counts (PHD array). For Pixel List, units are counts (generated histogram), angstroms (wavelength array), counts, pixel location, and angstroms, and seconds (pixel list array), counts per second (count rate array). 7.3.4 Additional FITS and PDS Keywords Added Below is an example of the Mike pipeline keyword block added to the FITS header: COMMENT ============================================= COMMENT MIKE_BEG= 'Feb 15 16:12:57 2005' / START MIKE KEYWORD BLOCK MIKE_VER= '2.0 [2005 Feb 15]' /Version of Mike pipeline code K_MODE = 'ACQMODE ' / Keyword containing the mode name K_ETIME = 'EXPTIME ' / Keyword for the effective exposure time FILE_IN = 'test/ali_0000006498_0x4b3_eng_1.fit' / Input file for processing FILE_OUT= 'test/test_his.fit' / Output file after processing DIR_CAL = 'cal/ ' / Directory of calibration data DIR_DONE= ' ' / Directory to put raw data after processing BADFILE = ' ' / FITS file of bad pixel mask array BADFLAG = -1 / Bad pixel mask flag BADVALUE= -666 / Bad pixel value DEADFILE= 'deadtime/ra_dead_002.txt' / Deadtime correction file DEADFLAG= 1 / DEADTYPE= 'FUN ' / Correct using FUNction or lookup table (LUT)? DEADCORR= 'TOTAL ' / Correct by TOTAL or each PIXEL count rate? BIASFILE= ' ' / Bias image filename BIASFLAG= -1 / Bias correction flag DARKFILE= 'dark/ra_dark_001.fit' / Dark image filename DARKFLAG= -1 / Dark correction flag FLATFILE= 'flat/ra_flat_001.fit' / Flag field image filename FLATFLAG= -1 / Flat field correction flag FLATNORM= 'AVERAGE ' / How to normalize flat field WCALFLAG= 0 / Wavelength calibration flag WCALPRO = 'alice_wavecal' / IDL program to perform wavelength calibration WCALPARS= 'T_DELECC' / keywords for parameters to use for wave cal AEFFFLAG= 1 / AEFFPRO = 'alice_aeff' / IDL program to get effective area AEFFPARS= 'T_DELECC' / keywords for parameters to get effective area LOG_FILE= 'test/log.out' / Filename to save log file (default = append to LOG_MAIL= ' ' / address (if any) to e-mail log file MIKE_ERR= 1 / MIKE_END= 'Tue Feb 15 16:12:57 2005' / END MIKE KEYWORD BLOCK COMMENT ============================================= COMMENT 7.3.5 Hardware/OS Development Platform Dell Linux, Redhat 7.2; Apple G5 Power PC and PowerBook G4, OS X v10.4 7.3.6 Language(s) Used IDL 7.3.7 Third Party Libraries Required IDL Astro (http://idlastro.gsfc.nasa.gov/) 7.3.8 Predicted Execution time A few seconds per file. 7.3.9 Contact/Support Person(s) Andrew Steffl, Joel Parker, and Maarten Versteeg 8. LEISA INSTRUMENT DESCRIPTION 8.1 Overview LEISA is an infrared imaging spectrometer. The detector is a 256x256 pixel array. Spectral separation is done with a wedged optical etalon filter placed in close proximity to the detector array. The filter is made of two pieces, a high spectral resolution (lambda/delta(lambda)=580) segment and a low spectral resolution (lambda/delta(lambda)=280) segment, bonded together. The detector-filter assembly is located at the plane of focus of the Ralph telescope where a 2-D image is recorded simultaneously with the infrared spectrum of the scene. The layout for the filter assembly is shown in Figure 8-0: Layout for LVF Filter Assembly. The wavelength range of the sensor is 1.225-2.5 nm for the low resolution segment and 2.1-2.25 microns for the high resolution segment. The wavelength of transmission of the filter varies along one axis and is constant in the other. Lines of constant wavelength are aligned with the row direction of the detector array. The number of pixel-limited spectral channels is the number of rows of the detector, excluding a number of rows (4) obscured by opaque adhesive at the bond joint between the two filter segments.

Figure 8-0: Layout for LVF Filter Assembly

The LEISA detector array is a Rockwell PICNIC device. It is read out

by the Ralph electronics in Correlated Double Sample (CDS) mode. The

signal is converted to a 12-bit value using the middle 12 bits of a 16

bit analog to digital (A/D) converter. There are two data transfer

modes, one in which both signal and reset level data are returned

(un-subtracted mode), and the other in which the reset level is

subtracted from the signal level and only the difference is returned

(subtracted mode).

The image cube is recorded as a series of N image frames, with N

determined by the length of the scan multiplied by the frame

rate. Detector frame rate is adjustable between 0.25 and 8 Hz in 1 ms

steps. Each frame covers the complete range of wavelengths. LEISA is

normally operated in a scanning mode, with the target moving through

the image plane, row by row. Slicing the image cube along one row

gives a scanned image of the target in one wavelength. Co-registering

each wavelength image (removing motion and optical distortion) yields

an IR spectrum of the target.

Data recorded on New Horizons is sent to the ground via the Deep Space

Network. From there the data is sent to the Mission Operations Center

(MOC) at the Applied Physics Laboratory (APL). The Science Operations

Center (SOC) retrieves new data from the MOC daily. The SOC software

pipelines convert the data from the MOC archives into FITS (Flexible

Image Transport) files with scientifically useful and calibrated

data. The SOC first sorts the packets into image cubes of raw (12-bit)

sensor counts with useful header keywords. These keywords include the

recording mode of the observation, timing information and basic

pointing information of the instrument boresight. The raw processing

also gathers housekeeping (H/K) telemetry from the Ralph instrument

into a table. Once the raw processing is complete, the SOC produced a

calibrated data set for each observation.

8.2 Raw Data Specifics

8.2.1 Data Format

Raw Dataset:

The SOC stores the LEISA data cubes in Band Interleaved by Line (BIL)

order, i.e. image frames are stored sequentially. To re-order LEISA

images as received from the spacecraft, the SOC does the following to

each frame of data:

1. de-interlace by quadrant

2. reverse the Y direction

3. rotate 180 degrees

The resulting frames from LEISA have the (0,0,0) element of the 3-D

array corresponds to the location of wavelength 2.5 microns on the LEISA

filter at the minimum X axis location in the image in the first

frame.

The SOC raw data product is a FITS format data file and PDS detached

label file. Ancillary data for an observation is placed in the primary

header of the FITS data file. The 256X256XN data cube is stored in

the primary data unit as an array of integers. The first FITS

extension is a binary table of Ralph housekeeping data.

Outline of the raw FITS file:

- Primary HDU - Raw 12 bit image counts

- Primary Header (FITS + pointing + observation keywords)

- 256 X 256 X N integer point array

- Extension 1 - Binary table of Ralph housekeeping

- Ext. Header (keywords + binary table definition)

- Ext. Binary Table (115 X S binary table of Ralph housekeeping data)

*[N is the number of data image frames in the observation, S is the

number of seconds in the observation]

**[In the case of un-subtracted readout mode, frames alternate between

read and reset signal levels]

Image Data

The primary data unit contains the raw spectral image data. Values

recorded by the instrument with 12 bit precision are stored as 16 bit

integers.

Housekeeping Data

Housekeeping data generated by the Ralph instrument is stored in

Extension 1 as a binary table. The first field in each row of the

table is mission elapsed tine (MET). Table entries are sorted by

increasing MET. The time interval between each table entry is fixed,

one second per entry, unless there is missing data. Pipeline

Processing

The limits of an observation are established by the SOC using

information in each telemetry packet of an observation sequence.

8.2.2 Data Sources (High/Low Speed, CCSDS, ITF)

Ralph housekeeping data is transmitted in the form of CCSDS packets.

One housekeeping packet is produced by the Ralph instrument each time

a spacecraft PPS (pulse per second) signal is received. State

information is gathered, time tagged, and written to the low speed bus

in CCSDS packet form. The CCSDS packets are transmitted during the

next DSN pass.

LEISA image data is transmitted in the form of CCSDS packets produced

by the spacecraft compression/packetization routines from the data

written to the high-speed bus. The LEISA detector has 4 output

channels, one for each array quadrant. The first 4 elements of the

data stream are the first pixels from each quadrant. The second 4

elements are the second pixels from each quadrant, and so on. One

'line' of data in this order is 4x 128 pixels long, and is not the

same as a line in the final image. During the observation, image data

is written to the spacecraft high speed bus. These data are not

automatically transmitted. A compression/packetization routine is

scheduled some time later that converts the Ralph sensor counts to a

packetized form.

The data can be packetized without compression, with lossless

compression, or with lossy JPEG compression. The packetization

routine can also process a sub-frame area of interest, or a more

complicated sliding subframe that tracks the image target as the

scanning observation proceeds. In un-subtracted readout mode, the

spacecraft interface supports only uncompressed downlink. Regardless

of windowing or compression, the SOC raw data processing reassembles

the data into a full 256X256XN data cube.

8.2.3 Definition of an "Observation"

Science Operation

The size of the LEISA detector is 256 x 256 pixels. One read out of

all 65,536 detector pixels is called an image or frame. The data

content of a LEISA "frame" is consistent with the S/C definition of

the term. The processing definition of "image" is consistent with the

optical definition except that the order of pixel elements is

different in the electronic data stream.

An observation is a sequence of frames. The number of frames per

observation is variable. Pixel values are recorded with 12 bit

precision. One image contains 65536 pixels x 1.5 bytes/pixel = 98304

bytes of data, however, data is stored as 16 bit values in the SOC

data files.

For normal science observations the Ralph electronics use the value of

the frame rate to minimize smearing by compensating for the spacecraft

motion and scan rate relative to the target. Reset levels are stored

temporarily by the electronics and subtracted from read levels

(subtracted mode). The difference in read and reset levels is

transferred to the spacecraft. Alternately, the instrument can be

forced to use a fixed frame rate value.

Un-subtracted Read-out:

There is a voltage offset for each LEISA quadrant to assure the sensor

signal will be in the correct range of the A/D. The offset values are

set from a table when Ralph is powered on. Un-subtracted mode can be

used to evaluate the offset values. In un-subtracted readout mode,

reset levels are not subtracted from read levels. Both read and reset

are transferred. The number of values in one data frame of the

un-subtracted mode (131,072) is 2x twice that of subtracted mode. Read

and reset values are interleaved by data line and the number and order

of the pixel elements in a line are the same as for subtracted mode

readout. The reset of a pixel occurs after the integrated signal is

read, so read levels correlate with reset levels recorded in the

preceding frame. The spacecraft interface supports only uncompressed

packetization of the full LEISA array for un-subtracted readout mode.

8.2.4 Housekeeping Needed in Level 1 Files (for Calibration)

Most of the H/K values are used for engineering troubleshooting and

not needed for data processing. Housekeeping data that are important

to further processing (see the following table) are stored in header

keywords.

Keyword Description

SIDE Instrument hardware side

DETECTOR Always LEISA for LEISA data

FILTER Always WEDGE for LEISA data

LEI_OFFx Value used to set voltage offsets for the four LEISA quadrants. x=1-4

LEI_RATE Time between LEISA readouts (ms)

8.2.5 Science Data and/or Housekeeping Requirements

Other important information is determined by the SOC while processing

the raw observation data. These values are also stored as keywords in

the FITS header.

Keyword Description

MET510 The MET of the Ralph housekeeping packet that marks the start

of an observation, used to determine the observation start time and

frame rate

TRUE510 Is the 0x510 real or assumed from a gap?

SCANTYPE Always LEISA for LEISA data

LEI_MODE RAW for un-subtracted readout mode

SUBTRACTED for subtracted readout mode

STARTMET Actual start time of first integration, in MET (s)

EXPTIME LEISA exposure time (s). Same as RALPHEXP.

There is zero dead time between frames so the

frame rate is exactly 1/EXPTIME

SPICE and SPICE Kernels:

The SOC maintains an archive of SPICE kernels that describe the

position and attitude of the spacecraft as any time in the mission.

The kernels are used to calculate many values describe the instrument

pointing during each observation, stored as header keywords with the

prefix SPC. The names of the SPICE kernels used to process the

observation are stored as header keywords with the prefix SPCK.

8.3 Calibrated Data Specifics

8.3.1 Algorithm for Pipeline

There are six processing steps applied to the raw LEISA data to produce the calibrated output:

1. Validate raw image file

2. Preprocess un-subtracted mode data

3. Process A/D rollover pixels

4. Convert raw counts to calibrated values

5. Compute pointing data

6. Construct FITS file

Validate raw image file

The input file is validated to assure the data is ready for further

8.processing. Checks are for valid mission, instrument, mode, and

8.image array size. The values of important keywords are validated

8.and collected in this step.

Preprocess un-subtracted mode data

If the data readout was in un-subtracted mode, the reset values are

subtracted from the read values in this step and the rest of the

processing is the same, regardless of readout mode.

Process A/D rollover pixels

There are two instances where the subtracted raw data value will be

off by exactly 4096 counts. The first is when the subtraction of the

reset count results in a negative number . This happens because of

array noise and read noise and results in small negative numbers being

returned as large positive number.s. The second instance is when the

subtraction of the reset count results in a number greater than 4095

(12 bits). This happens because the most significant bit of the A/D

is not read. A count higher than 4095 is normally considered outside

of dynamic range of LEISA, but can be corrected on a case by case

bases.

If a file identifying rollover pixels for the observation exists (see

next paragraph), the identified pixels are corrected for rollover. If

no file exists, any subtracted count greater than 3850 is considered

to have rolled over, and 4096 is subtracted from the raw count value.

This is a good first-cut since the observations will not be designed

to return signal counts this high.

During initial image analysis by the Ralph team, each observation is

analyzed in detail. A file identifying rollover pixels is generated

which identifies the pixels that are deemed to need rollover

correction. The case where the read count is higher than 4095 can be

detected by analyzing surrounding pixels and by watching the target

scan through the array. These are also included in the rollover file.

Once this file is installed on the SOC, processing of the calibrated

data for the observation will automatically use the rollover file

instead of the default processing.

Convert raw counts to calibrated values

There are 8 values that make up the conversion between raw signal

count and calibrated signal value.

1. Electronics induced readout signal

2. CCD flat field

3. Calibration offset

4. Calibration gain

5. Integration time

6. Filter width

7. Pixel solid angle

8. Gain correction

The electronics induced readout signal is a base signal that does not

depend on integration time. It has been derived from studies of the

dark frames of flight data and is subtracted from the raw signal

count.

The CCD flat field is derived from laboratory data and refined with in

flight observation data. The flat field changes slightly as the

mission progresses so a different flat field can be defined for an

individual observation or a range of observations. The actual flat

field used in the processing is included in the output FITS file.

The calibration offsets and calibration gains are derived from

laboratory data and refined with in flight observation data. These

values can change as the mission progresses. Different calibration

values can be defined for an individual observation or a range of

observations. The actual calibration values used in the processing

are included in the output FITS file.

The integration time is divided into the calculated calibrated counts.

The filter width of each pixel is divided into the calculated calibrated counts.

The pixel solid angle is divided into the calculated calibrated counts.

The gain correction is divided into the calculated calibrated counts.

All of these values are derived from laboratory data and refined with

in flight calibration observation data. They are updated, as needed

an applied to the observation data automatically when re-processed

Compute pointing data

The pointing for each pixel of each frame is computed using the timing

information from the observation, reconstructed ephemeris and attitude

files, and knowledge of the optical distortion of the instrument. One

array is generated giving the cartesian pointing vector of each pixel

in the LEISA array. This is a function only of the optical distortion

of the system. A second array is generated giving the rotation

quaternion of the instrument boresight into the J2000 reference frame

for the middle of each exposure. By rotating the pointing vector of a

pixel by the quaternion for the image frame, the J2000 pointing vector

of each pixel can be derived

Construct FITS files

A FITS file is constructed to store all the calibrated image data and related processing data.

8.3.2 Dataflow Block Diagram

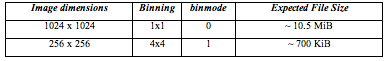

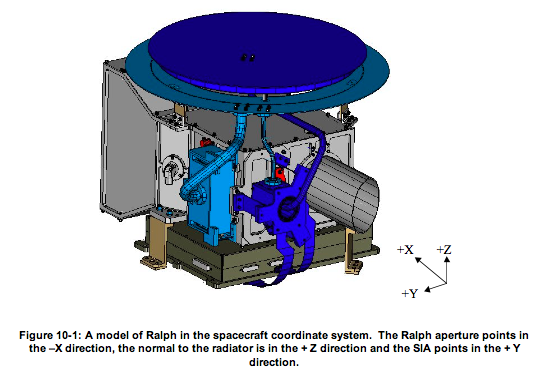

Figure 8-0: Layout for LVF Filter Assembly

The LEISA detector array is a Rockwell PICNIC device. It is read out

by the Ralph electronics in Correlated Double Sample (CDS) mode. The

signal is converted to a 12-bit value using the middle 12 bits of a 16

bit analog to digital (A/D) converter. There are two data transfer

modes, one in which both signal and reset level data are returned

(un-subtracted mode), and the other in which the reset level is

subtracted from the signal level and only the difference is returned

(subtracted mode).

The image cube is recorded as a series of N image frames, with N

determined by the length of the scan multiplied by the frame

rate. Detector frame rate is adjustable between 0.25 and 8 Hz in 1 ms

steps. Each frame covers the complete range of wavelengths. LEISA is

normally operated in a scanning mode, with the target moving through

the image plane, row by row. Slicing the image cube along one row

gives a scanned image of the target in one wavelength. Co-registering

each wavelength image (removing motion and optical distortion) yields

an IR spectrum of the target.

Data recorded on New Horizons is sent to the ground via the Deep Space

Network. From there the data is sent to the Mission Operations Center

(MOC) at the Applied Physics Laboratory (APL). The Science Operations

Center (SOC) retrieves new data from the MOC daily. The SOC software

pipelines convert the data from the MOC archives into FITS (Flexible

Image Transport) files with scientifically useful and calibrated

data. The SOC first sorts the packets into image cubes of raw (12-bit)

sensor counts with useful header keywords. These keywords include the

recording mode of the observation, timing information and basic

pointing information of the instrument boresight. The raw processing

also gathers housekeeping (H/K) telemetry from the Ralph instrument

into a table. Once the raw processing is complete, the SOC produced a

calibrated data set for each observation.

8.2 Raw Data Specifics

8.2.1 Data Format

Raw Dataset:

The SOC stores the LEISA data cubes in Band Interleaved by Line (BIL)

order, i.e. image frames are stored sequentially. To re-order LEISA

images as received from the spacecraft, the SOC does the following to

each frame of data:

1. de-interlace by quadrant

2. reverse the Y direction

3. rotate 180 degrees

The resulting frames from LEISA have the (0,0,0) element of the 3-D

array corresponds to the location of wavelength 2.5 microns on the LEISA

filter at the minimum X axis location in the image in the first

frame.

The SOC raw data product is a FITS format data file and PDS detached

label file. Ancillary data for an observation is placed in the primary

header of the FITS data file. The 256X256XN data cube is stored in

the primary data unit as an array of integers. The first FITS

extension is a binary table of Ralph housekeeping data.

Outline of the raw FITS file:

- Primary HDU - Raw 12 bit image counts

- Primary Header (FITS + pointing + observation keywords)

- 256 X 256 X N integer point array

- Extension 1 - Binary table of Ralph housekeeping

- Ext. Header (keywords + binary table definition)

- Ext. Binary Table (115 X S binary table of Ralph housekeeping data)

*[N is the number of data image frames in the observation, S is the

number of seconds in the observation]

**[In the case of un-subtracted readout mode, frames alternate between

read and reset signal levels]

Image Data

The primary data unit contains the raw spectral image data. Values

recorded by the instrument with 12 bit precision are stored as 16 bit

integers.

Housekeeping Data

Housekeeping data generated by the Ralph instrument is stored in

Extension 1 as a binary table. The first field in each row of the

table is mission elapsed tine (MET). Table entries are sorted by

increasing MET. The time interval between each table entry is fixed,

one second per entry, unless there is missing data. Pipeline

Processing

The limits of an observation are established by the SOC using

information in each telemetry packet of an observation sequence.

8.2.2 Data Sources (High/Low Speed, CCSDS, ITF)

Ralph housekeeping data is transmitted in the form of CCSDS packets.

One housekeeping packet is produced by the Ralph instrument each time

a spacecraft PPS (pulse per second) signal is received. State

information is gathered, time tagged, and written to the low speed bus

in CCSDS packet form. The CCSDS packets are transmitted during the

next DSN pass.

LEISA image data is transmitted in the form of CCSDS packets produced

by the spacecraft compression/packetization routines from the data

written to the high-speed bus. The LEISA detector has 4 output

channels, one for each array quadrant. The first 4 elements of the

data stream are the first pixels from each quadrant. The second 4

elements are the second pixels from each quadrant, and so on. One

'line' of data in this order is 4x 128 pixels long, and is not the

same as a line in the final image. During the observation, image data

is written to the spacecraft high speed bus. These data are not

automatically transmitted. A compression/packetization routine is

scheduled some time later that converts the Ralph sensor counts to a

packetized form.

The data can be packetized without compression, with lossless

compression, or with lossy JPEG compression. The packetization

routine can also process a sub-frame area of interest, or a more

complicated sliding subframe that tracks the image target as the

scanning observation proceeds. In un-subtracted readout mode, the

spacecraft interface supports only uncompressed downlink. Regardless

of windowing or compression, the SOC raw data processing reassembles

the data into a full 256X256XN data cube.

8.2.3 Definition of an "Observation"

Science Operation

The size of the LEISA detector is 256 x 256 pixels. One read out of

all 65,536 detector pixels is called an image or frame. The data

content of a LEISA "frame" is consistent with the S/C definition of

the term. The processing definition of "image" is consistent with the

optical definition except that the order of pixel elements is

different in the electronic data stream.

An observation is a sequence of frames. The number of frames per

observation is variable. Pixel values are recorded with 12 bit

precision. One image contains 65536 pixels x 1.5 bytes/pixel = 98304

bytes of data, however, data is stored as 16 bit values in the SOC

data files.

For normal science observations the Ralph electronics use the value of

the frame rate to minimize smearing by compensating for the spacecraft

motion and scan rate relative to the target. Reset levels are stored

temporarily by the electronics and subtracted from read levels

(subtracted mode). The difference in read and reset levels is

transferred to the spacecraft. Alternately, the instrument can be

forced to use a fixed frame rate value.

Un-subtracted Read-out:

There is a voltage offset for each LEISA quadrant to assure the sensor

signal will be in the correct range of the A/D. The offset values are

set from a table when Ralph is powered on. Un-subtracted mode can be

used to evaluate the offset values. In un-subtracted readout mode,

reset levels are not subtracted from read levels. Both read and reset

are transferred. The number of values in one data frame of the

un-subtracted mode (131,072) is 2x twice that of subtracted mode. Read

and reset values are interleaved by data line and the number and order

of the pixel elements in a line are the same as for subtracted mode

readout. The reset of a pixel occurs after the integrated signal is

read, so read levels correlate with reset levels recorded in the

preceding frame. The spacecraft interface supports only uncompressed

packetization of the full LEISA array for un-subtracted readout mode.

8.2.4 Housekeeping Needed in Level 1 Files (for Calibration)

Most of the H/K values are used for engineering troubleshooting and

not needed for data processing. Housekeeping data that are important

to further processing (see the following table) are stored in header

keywords.

Keyword Description

SIDE Instrument hardware side

DETECTOR Always LEISA for LEISA data

FILTER Always WEDGE for LEISA data

LEI_OFFx Value used to set voltage offsets for the four LEISA quadrants. x=1-4

LEI_RATE Time between LEISA readouts (ms)

8.2.5 Science Data and/or Housekeeping Requirements

Other important information is determined by the SOC while processing

the raw observation data. These values are also stored as keywords in

the FITS header.

Keyword Description

MET510 The MET of the Ralph housekeeping packet that marks the start

of an observation, used to determine the observation start time and

frame rate

TRUE510 Is the 0x510 real or assumed from a gap?

SCANTYPE Always LEISA for LEISA data

LEI_MODE RAW for un-subtracted readout mode

SUBTRACTED for subtracted readout mode

STARTMET Actual start time of first integration, in MET (s)

EXPTIME LEISA exposure time (s). Same as RALPHEXP.

There is zero dead time between frames so the

frame rate is exactly 1/EXPTIME

SPICE and SPICE Kernels:

The SOC maintains an archive of SPICE kernels that describe the

position and attitude of the spacecraft as any time in the mission.

The kernels are used to calculate many values describe the instrument

pointing during each observation, stored as header keywords with the

prefix SPC. The names of the SPICE kernels used to process the

observation are stored as header keywords with the prefix SPCK.

8.3 Calibrated Data Specifics

8.3.1 Algorithm for Pipeline

There are six processing steps applied to the raw LEISA data to produce the calibrated output:

1. Validate raw image file

2. Preprocess un-subtracted mode data

3. Process A/D rollover pixels

4. Convert raw counts to calibrated values

5. Compute pointing data

6. Construct FITS file

Validate raw image file

The input file is validated to assure the data is ready for further

8.processing. Checks are for valid mission, instrument, mode, and

8.image array size. The values of important keywords are validated

8.and collected in this step.

Preprocess un-subtracted mode data

If the data readout was in un-subtracted mode, the reset values are

subtracted from the read values in this step and the rest of the

processing is the same, regardless of readout mode.

Process A/D rollover pixels

There are two instances where the subtracted raw data value will be

off by exactly 4096 counts. The first is when the subtraction of the

reset count results in a negative number . This happens because of

array noise and read noise and results in small negative numbers being

returned as large positive number.s. The second instance is when the

subtraction of the reset count results in a number greater than 4095

(12 bits). This happens because the most significant bit of the A/D

is not read. A count higher than 4095 is normally considered outside

of dynamic range of LEISA, but can be corrected on a case by case

bases.

If a file identifying rollover pixels for the observation exists (see

next paragraph), the identified pixels are corrected for rollover. If

no file exists, any subtracted count greater than 3850 is considered

to have rolled over, and 4096 is subtracted from the raw count value.

This is a good first-cut since the observations will not be designed

to return signal counts this high.

During initial image analysis by the Ralph team, each observation is

analyzed in detail. A file identifying rollover pixels is generated

which identifies the pixels that are deemed to need rollover

correction. The case where the read count is higher than 4095 can be

detected by analyzing surrounding pixels and by watching the target

scan through the array. These are also included in the rollover file.

Once this file is installed on the SOC, processing of the calibrated

data for the observation will automatically use the rollover file

instead of the default processing.

Convert raw counts to calibrated values

There are 8 values that make up the conversion between raw signal

count and calibrated signal value.

1. Electronics induced readout signal

2. CCD flat field

3. Calibration offset

4. Calibration gain

5. Integration time

6. Filter width

7. Pixel solid angle

8. Gain correction

The electronics induced readout signal is a base signal that does not

depend on integration time. It has been derived from studies of the

dark frames of flight data and is subtracted from the raw signal

count.

The CCD flat field is derived from laboratory data and refined with in

flight observation data. The flat field changes slightly as the

mission progresses so a different flat field can be defined for an

individual observation or a range of observations. The actual flat

field used in the processing is included in the output FITS file.

The calibration offsets and calibration gains are derived from

laboratory data and refined with in flight observation data. These

values can change as the mission progresses. Different calibration

values can be defined for an individual observation or a range of

observations. The actual calibration values used in the processing

are included in the output FITS file.

The integration time is divided into the calculated calibrated counts.

The filter width of each pixel is divided into the calculated calibrated counts.

The pixel solid angle is divided into the calculated calibrated counts.

The gain correction is divided into the calculated calibrated counts.

All of these values are derived from laboratory data and refined with

in flight calibration observation data. They are updated, as needed

an applied to the observation data automatically when re-processed

Compute pointing data

The pointing for each pixel of each frame is computed using the timing

information from the observation, reconstructed ephemeris and attitude

files, and knowledge of the optical distortion of the instrument. One

array is generated giving the cartesian pointing vector of each pixel

in the LEISA array. This is a function only of the optical distortion

of the system. A second array is generated giving the rotation

quaternion of the instrument boresight into the J2000 reference frame

for the middle of each exposure. By rotating the pointing vector of a

pixel by the quaternion for the image frame, the J2000 pointing vector

of each pixel can be derived

Construct FITS files

A FITS file is constructed to store all the calibrated image data and related processing data.

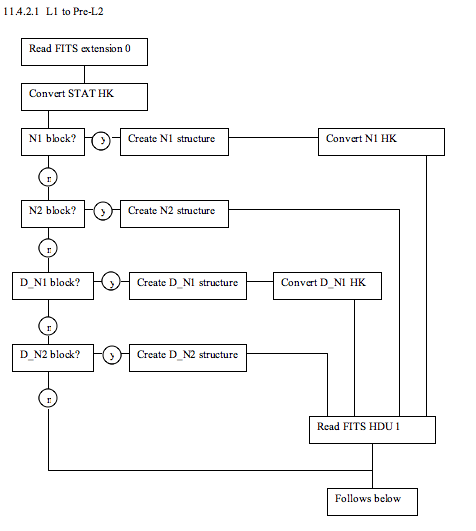

8.3.2 Dataflow Block Diagram

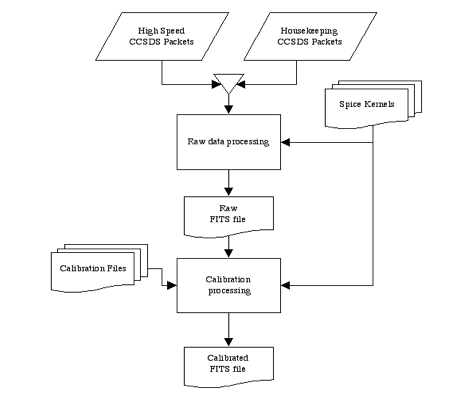

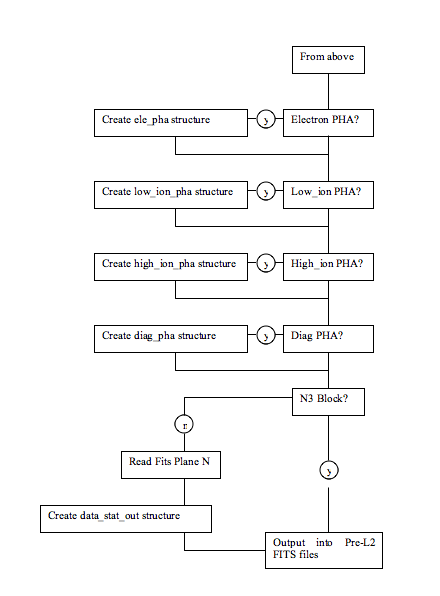

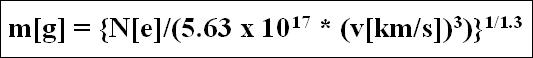

Figure 8-1: Dataflow Block Diagram

8.3.3 Data Format

Calibrated Dataset

The calibrated LEISA data are stored in Band Interleaved by Line (BIL)

order, exactly as the raw data is stored. The resulting frames from

LEISA have the (0,0,0) element of the 3-D array corresponds to the

location of wavelength 2.5 microns on the LEISA filter at the minimum X

axis location in the image in the first frame.

The calibrated data product is a FITS format data file and PDS

detached label file. Ancillary data for an observation is placed in

the primary header of the FITS data file. The 256X256XN data cube is

stored in the primary data unit as an array of floating point numbers.

The FITS extensions are outlined below.

Outline of the calibrated FITS file:

- Primary HDU - Calibrated image data

- Primary Header (FITS + pointing + observation keywords)

- 256 X 256 X N floating point array

- Extension 1 - Center wavelength and filter width for each pixel

- 256 X 256 X 2 floating point array

- Extension 2 - Cartesian pointing vector for each pixel

- 256 X 256 X 3 floating point array

- Extension 3 - Flat field correction for each pixel

- 256 X 256 X 1 floating point array

- Extension 4 - Radiometric gain and offset for each pixel

- 256 X 256 X 2 floating point array

- Extension 5 - Error estimates for each pixel

- 256 X 256 X 1 floating point array

- Extension 6 - Data quality flags for each pixel

- 256 X 256 X 1 Integer array

- Extension 7 - Ephemeris time and quaternion for each frame

- 5 X N floating point array

- Extension 8 - Binary table of Ralph housekeeping

- Ext. Header (keywords + binary table definition)

- Ext. Binary Table (115 X S binary table of Ralph housekeeping data)

*[N is the number of data image frames in the observation, S is the

number of seconds in the observation]

For a description of the contents of the FITS extension, see the above

section describing the SOC calibration processing.

Calibrated Image Data

The Image Data Unit of the Level 2 file contains data expressed in

physical units useful for scientific interpretation. The instrument

pipeline converts the data values of raw instrument counts to

radiance units, W/cm2/sr.

Data quality flags

The data quality flag is set if there is a known problem with the

given pixel.

Quality Flag Value Description

0 Good pixel

1 Defect in one of the calibration files

2 Flat field out of bounds

4 Known CCD defect

32 Bad pixel not in any of above categories

8.3.4 Extra FITS Extensions (planes) and Their Definitions

See above

8.3.5 Scientific Units

Radiometric units: W/cm2/sr

8.3.6 Additional FITS and PDS Keywords Added

See above

8.3.7 Hardware/OS Development Platform

The software for processing the raw and calibrated data files has been developed on the SOC computers, running GNU/Linux/i686 Version 2.6.17-1.2142_FC4.

8.3.8 Language(s) Used

The software for processing the raw data files is written in Python.

The software for processing the calibrated data files is written in C, with a Perl script wrapper.

8.3.9 Third Party Libraries Required

Python SPYCE interface library

Python MySQLdb interface library

Independent JPEG Group's JPEG software

CSPICE processing library

CFITSIO processing library

8.3.10 Calibration Files Needed (with Quantities)

The instrument software package will include additional datasets needed for calibrating the data. All The calibration software requires additional datasets needed for calibrating the data, as describe in the above sections. The instrument pipeline maintains version control on calibration datasets, as with calibration procedures. Some calibration files are associated with specific observations, some are associated with a range of observations.

The estimated number of calibration files needed for the mission is 300, totaling 3 GBs.

8.3.11 Memory Required

500MB

8.3.12 Temporary File System Space Needed

500MB

8.3.13 Predicted Size of Output File(s)

Up to 500MB

8.3.14 Predicted Execution time

Processing time for raw data files is approximately 3 seconds per image frame.

Processing time for calibrated data files is approximately .1 seconds per frame

8.3.15 Contact/Support Person(s)

Allen Lunsford

Dennis Reuter 301-286-2042

Donald Jennings 301-286-7701

Laddawan Miko 301-286-2166

8.3.16 Maintenance Schedule (Code/Data Updates, Documentation)

The LPS is installed by extracting files from an archive. The

sub-directory structure for the software package is created during

extraction. Symbolic links to external directories may be substituted

for default directory references. The shell for execution of the LPS

is tcsh/csh. Changes will be made to shell initialization files; new

elements are appended. Instructions for configuring the shell

environment are given. A guide to installation and setup is included

with the LPS package.

An initial period of testing and refinements is expected. Pieces of

the software are tested separately during development. LPS modules are

re-tested upon installation to the SOC. Sample datasets are provided

to verify the function of software. Integrated testing of the

instrument pipeline under the control of the SOC MDM is performed in

accordance with the SOC. The instrument software engineer is available

exclusively to the SOC to support the integration of pipeline

software.

Changes to calibration datasets are made as needed. A facility is

provided by the SOC so that software changes are reversible. A LEISA

team member will be available to assist SOC operators in responding to

unexpected errors in the instrument pipeline. Persons supporting the

LEISA Instrument Pipeline software are listed above.

The LEISA instrument pipeline is developed at GSFC. The first fully

functional version (v0) of the software is tested on the GSFC computer

system. In advance of completion of LPS v0, a skeleton software

package will be made available to the SOC. The skeleton software is a

callable code set which installs and functions as the instrument

pipeline but does not perform calibration and book keeping on

instrument data. Completion of software Version 0 encompasses the

creation of instrument calibration files. Documentation including

instructions for installation and setup will be delivered to the SOC

with Version 1 of the LPS. Updates of software after Version 1 are

performed on an as needed basis.

Figure 8-1: Dataflow Block Diagram

8.3.3 Data Format

Calibrated Dataset

The calibrated LEISA data are stored in Band Interleaved by Line (BIL)

order, exactly as the raw data is stored. The resulting frames from

LEISA have the (0,0,0) element of the 3-D array corresponds to the

location of wavelength 2.5 microns on the LEISA filter at the minimum X

axis location in the image in the first frame.

The calibrated data product is a FITS format data file and PDS

detached label file. Ancillary data for an observation is placed in

the primary header of the FITS data file. The 256X256XN data cube is

stored in the primary data unit as an array of floating point numbers.

The FITS extensions are outlined below.

Outline of the calibrated FITS file:

- Primary HDU - Calibrated image data

- Primary Header (FITS + pointing + observation keywords)

- 256 X 256 X N floating point array

- Extension 1 - Center wavelength and filter width for each pixel

- 256 X 256 X 2 floating point array

- Extension 2 - Cartesian pointing vector for each pixel

- 256 X 256 X 3 floating point array

- Extension 3 - Flat field correction for each pixel

- 256 X 256 X 1 floating point array

- Extension 4 - Radiometric gain and offset for each pixel

- 256 X 256 X 2 floating point array

- Extension 5 - Error estimates for each pixel

- 256 X 256 X 1 floating point array

- Extension 6 - Data quality flags for each pixel

- 256 X 256 X 1 Integer array

- Extension 7 - Ephemeris time and quaternion for each frame

- 5 X N floating point array

- Extension 8 - Binary table of Ralph housekeeping

- Ext. Header (keywords + binary table definition)

- Ext. Binary Table (115 X S binary table of Ralph housekeeping data)

*[N is the number of data image frames in the observation, S is the

number of seconds in the observation]

For a description of the contents of the FITS extension, see the above

section describing the SOC calibration processing.

Calibrated Image Data

The Image Data Unit of the Level 2 file contains data expressed in

physical units useful for scientific interpretation. The instrument

pipeline converts the data values of raw instrument counts to

radiance units, W/cm2/sr.

Data quality flags

The data quality flag is set if there is a known problem with the

given pixel.

Quality Flag Value Description

0 Good pixel

1 Defect in one of the calibration files

2 Flat field out of bounds

4 Known CCD defect

32 Bad pixel not in any of above categories

8.3.4 Extra FITS Extensions (planes) and Their Definitions

See above

8.3.5 Scientific Units

Radiometric units: W/cm2/sr

8.3.6 Additional FITS and PDS Keywords Added

See above

8.3.7 Hardware/OS Development Platform

The software for processing the raw and calibrated data files has been developed on the SOC computers, running GNU/Linux/i686 Version 2.6.17-1.2142_FC4.

8.3.8 Language(s) Used

The software for processing the raw data files is written in Python.

The software for processing the calibrated data files is written in C, with a Perl script wrapper.

8.3.9 Third Party Libraries Required

Python SPYCE interface library

Python MySQLdb interface library

Independent JPEG Group's JPEG software

CSPICE processing library

CFITSIO processing library

8.3.10 Calibration Files Needed (with Quantities)

The instrument software package will include additional datasets needed for calibrating the data. All The calibration software requires additional datasets needed for calibrating the data, as describe in the above sections. The instrument pipeline maintains version control on calibration datasets, as with calibration procedures. Some calibration files are associated with specific observations, some are associated with a range of observations.

The estimated number of calibration files needed for the mission is 300, totaling 3 GBs.

8.3.11 Memory Required

500MB

8.3.12 Temporary File System Space Needed

500MB

8.3.13 Predicted Size of Output File(s)

Up to 500MB

8.3.14 Predicted Execution time

Processing time for raw data files is approximately 3 seconds per image frame.

Processing time for calibrated data files is approximately .1 seconds per frame

8.3.15 Contact/Support Person(s)

Allen Lunsford

Dennis Reuter 301-286-2042

Donald Jennings 301-286-7701

Laddawan Miko 301-286-2166

8.3.16 Maintenance Schedule (Code/Data Updates, Documentation)

The LPS is installed by extracting files from an archive. The

sub-directory structure for the software package is created during

extraction. Symbolic links to external directories may be substituted

for default directory references. The shell for execution of the LPS

is tcsh/csh. Changes will be made to shell initialization files; new

elements are appended. Instructions for configuring the shell

environment are given. A guide to installation and setup is included

with the LPS package.

An initial period of testing and refinements is expected. Pieces of

the software are tested separately during development. LPS modules are

re-tested upon installation to the SOC. Sample datasets are provided

to verify the function of software. Integrated testing of the

instrument pipeline under the control of the SOC MDM is performed in

accordance with the SOC. The instrument software engineer is available

exclusively to the SOC to support the integration of pipeline

software.

Changes to calibration datasets are made as needed. A facility is

provided by the SOC so that software changes are reversible. A LEISA

team member will be available to assist SOC operators in responding to

unexpected errors in the instrument pipeline. Persons supporting the

LEISA Instrument Pipeline software are listed above.

The LEISA instrument pipeline is developed at GSFC. The first fully

functional version (v0) of the software is tested on the GSFC computer

system. In advance of completion of LPS v0, a skeleton software

package will be made available to the SOC. The skeleton software is a

callable code set which installs and functions as the instrument

pipeline but does not perform calibration and book keeping on

instrument data. Completion of software Version 0 encompasses the

creation of instrument calibration files. Documentation including

instructions for installation and setup will be delivered to the SOC

with Version 1 of the LPS. Updates of software after Version 1 are

performed on an as needed basis.

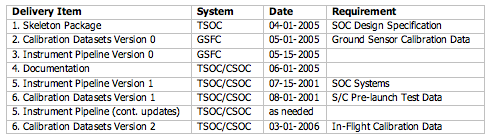

Table 8-1

Table 8-1

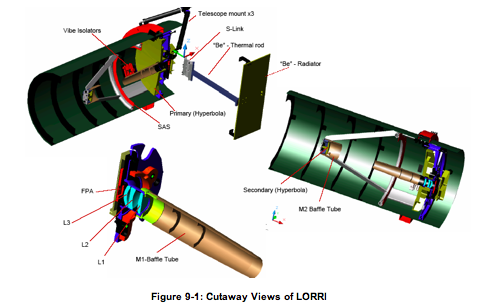

Table 8-1 9. LORRI INSTRUMENT DESCRIPTION 9.1 Overview The LOng Range Reconnaissance Imager (LORRI) is a narrow angle (FOV=0.29degrees), high resolution (IFOV=5 microrad), Ritchey-Chretien telescope with a 20.8 cm diameter primary mirror, a focal length of 263 cm, and a three lens field-flattening assembly. A 1024 x 1024 pixel (optically active region), back-thinned, backside-illuminated CCD detector (model CCD 47-20 from E2V) is located at the telescope focal plane and is operated in standard frame-transfer mode. LORRI does not have any color filters; it provides panchromatic imaging over a wide bandpass extending approximately from 350 nm to 850 nm. The LORRI telescope has a monolithic silicon carbide structure, built by SSG Precision Optronics, Inc., is designed to maintain focus over the entire operating temperature range (-125 C to +40 C) without a focus adjustment mechanism. A detailed description of the design and fabrication of LORRI can be found in the paper by Conard, et al., "Design and fabrication of the New Horizons Long-Range Reconnaissance Imager" in SPIE proceedings 5906-49, 2005. A detailed discussion of the performance of LORRI, as measured during calibration testing before launch, can be found in the paper by Morgan et al., "Calibration of the New Horizons Long-Range Reconnaissance Image" in SPIE proceedings 5606-49, 2005. LORRI is a supplemental instrument on New Horizons and is not needed to meet the baseline scientific objectives of the mission. Nevertheless, LORRI adds significant capabilities to New Horizons, including the highest available spatial resolution (50 m/pixel at the Pluto closest approach distance of 10,000 km) and redundancy for the primary optical imager, MVIC on Ralph. The exposure time for LORRI is adjustable in 1 msec increments from 0 ms to 29,967 msec. However, exposure times will normally be limited to < 150 msec to prevent image smear associated with spacecraft motion during observations. Initially, the shortest useful exposure time was expected to be ~40 msec owing to frame transfer smear associated with the transfer of charge from the active CCD region to the storage region, during which time the active region remains exposed to the image scene because LORRI has no shutter, but an improved frame transfer smear removal algorithm was developed that now permits exposure times as little as 1 msec. The LORRI exposure time can be commanded to a specific value, or LORRI can be operated in "auto-exposure" mode, in which the LORRI flight software sets the exposure time automatically based on the signal level in a previous image. In auto-exposure mode, the algorithm used to set the exposure time depends on several adjustable parameters that are stored in an onboard table. The optimal values for these table parameters vary with the type of scene being observed, which means that new table loads may be required prior to some observations. Although the LORRI auto-exposure mode worked well during ground testing, no decision has yet been made on whether it will be used in-flight during encounter observations. LORRI can also be operated in "rebin" mode, in which case the signal in a 4 x 4 pixel region is summed on-chip to produce an active region that is effectively 256 x 256 pixels covering the entire 0.29 degrees FOV. The main purpose of this mode is to provide high sensitivity acquisition of a Kuiper Belt object (KBO), which requires an exposure time of ~10 sec. Although LORRI rebin mode may never be used for science observations, the LORRI pipeline is still required to calibrate rebinned images.

Figure 9-1: Cutaway Views of LORRI

9.2 Raw image Specifics

9.2.1 Data Format

The raw image data is organized in a FITS file. The primary header

9.and data unit (HDU) is used to store the reconstructed image from

9.telemetry. Additional data are stored in the extensions of the

9.file. The two tables below contain a description of the layout for

9.the extensions for raw data.

As described previously, LORRI operates in two binning modes: 1x1 and

4x4. For the 1x1 binning mode, the raw image dimensions are 1028x1024

where columns 0 through 1023 are the optically active region of the

CCD and the remaining columns (1024-1027) are from optically inactive

region (dark columns) of the CCD and represent a temperature-specific

measurement of the bias value. For the 4x4 binning mode, the raw

image dimensions ar 257 x 256 where columns 0 through 255 are

optically active and column 256 for the dark column.

Figure 9-1: Cutaway Views of LORRI

9.2 Raw image Specifics

9.2.1 Data Format

The raw image data is organized in a FITS file. The primary header

9.and data unit (HDU) is used to store the reconstructed image from

9.telemetry. Additional data are stored in the extensions of the

9.file. The two tables below contain a description of the layout for

9.the extensions for raw data.

As described previously, LORRI operates in two binning modes: 1x1 and

4x4. For the 1x1 binning mode, the raw image dimensions are 1028x1024

where columns 0 through 1023 are the optically active region of the

CCD and the remaining columns (1024-1027) are from optically inactive

region (dark columns) of the CCD and represent a temperature-specific

measurement of the bias value. For the 4x4 binning mode, the raw

image dimensions ar 257 x 256 where columns 0 through 255 are

optically active and column 256 for the dark column.

Table 9-5

Table 9-5

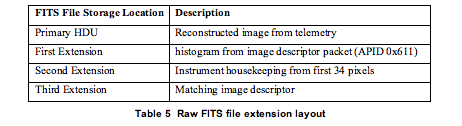

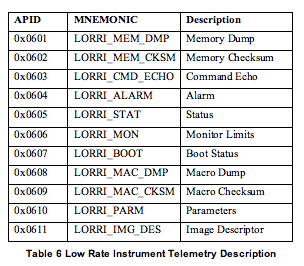

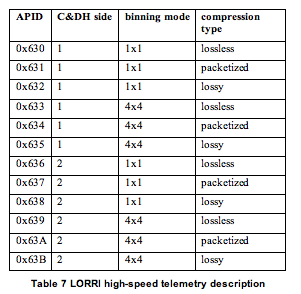

Table 9-5: Raw FITS file extension layout 9.2.2 Data Sources (High/Low Speed, CCSDS, ITF) The LORRI high-rate data is delivered to the Instrument Interface card over a low-voltage differential signal (LVDS) interface and is then transferred to the SSR through the spacecraft high-speed PCI bus by the C&DH software. The image data is stored directly on the SSR and packets are generated by command to the C&DH software as is described in the table below. The APID from which the image originated is part of the filename, so this mapping may provide some assistance in decoding the filenames retrieved from the SOC.

Table 9-6

Table 9-6

Table 9-6: Low Rate Instrument Telemetry Description

Table 9-7

Table 9-7

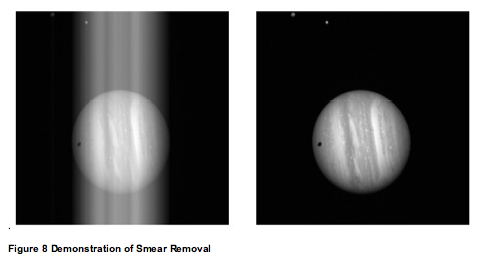

Table 9-7: LORRI high-speed telemetry description 9.2.3 Definition of an "Observation" Each LORRI image is an "observation." 9.2.4 Housekeeping Needed in Raw Image Files (for Calibration) No special requirements other than pointing 9.2.5 Raw Science Data and/or Housekeeping Requirements No special requirements 9.3 Calibrated Image Specifics 9.3.1 Algorithms for Pipeline Calibration Process The calibration of LORRI images potentially involves all of the following steps: 1) Bias subtraction 2) Signal linearization 3) Charge transfer inefficiency (CTI) correction 4) Dark subtraction 5) Smear removal 6) Flat-fielding 7) Absolute calibration Ground testing has demonstrated that the linearization, CTI, and dark subtraction steps will not be needed, so they are not described below. Nevertheless, the LORRI pipeline architecture will be maintained to allow these additional steps to be incorporated quickly, if in-flight data suggest they are needed. The LORRI pipeline software consists of a series of IDL routines that implement the above processing steps. In general, the IDL routines have the following naming convention: lorri_function.pro, where "function" refers to the specific task performed by that routine. (The "pro" extension will be omitted below when discussing specific routines.) Each routine typically has several command line arguments and keywords that specify the input and output files and, possibly, parameters for tailoring the routine for particular circumstances. The routines that perform the bias subtraction, the smear removal, and the flat-fielding are described below. No special routines are provided to perform the absolute calibration. Instead, the absolute calibration is performed using keywords provided in the FITS header, as described further in Section 9.3.1.4. 9.3.1.1 Bias Subtraction If an image has an associated "dark" image (i.e., an image taken with the same exposure time but without any illumination), then the debiased image is simply the difference of those two images. This was usually the case during on-ground testing when images taken of a scene were immediately followed by images taken with the scene blocked (i.e., an obstruction was placed in the optical path to block the illumination). However, in-flight images may often be taken without accompanying darks either because of limitations on downlink bandwidth, or because a decision is made to take more target images at the expense of concurrent darks. In either case, the same pipeline routine will be used to debias the image (lorri_debias), but the algorithm employed is different in each case and different reference files are required. If in-flight data indicate that bias images are stable over time, many bias images will be combined (after filtering out clearly discrepant pixels) to produce a "super-bias" image. Then the median value of the inactive region of the image (i.e., the median of a 1024 row by 4 column region) is subtracted from the super-bias image to produce a "delta-bias" image. The IDL procedure that produces the delta-bias image is called lorri_delta_bias, but this routine is not part of the standard LORRI calibration pipeline; rather, it is an ancillary routine used to produce a calibration reference file. The delta-bias image will exhibit the pixel-to-pixel variation in the bias and will oscillate about zero. The bias subtraction for any new image is then a two-step process: 1) The median signal level in the inactive region of the image is subtracted from each pixel's value to remove the overall bias level, and 2) The delta-bias image is subtracted from the image created in the previous step to remove the pixel-to-pixel variation and produce the final, debiased image. Ground calibration testing showed that the overall bias level in step (1) above depends on the signal level in the last few columns of the active region of the CCD. The effect is produced by amplifier undershoot, which means that the bias level recorded by the pixels in the inactive region is smaller than the actual bias level. The magnitude of the effect depends on the signal level in the active region and on the column number in the inactive region and can be as large as ~12 DN. Thus, prior to computing the median signal in the inactive region (step 1 above), the intensities of all the pixels must be corrected for amplifier undershoot. This correction step is incorporated into the lorri_debias procedure. If the in-flight bias images vary significantly in time, separate bias images (i.e., 0 ms exposures) must be taken for each science image obtained. In this case, the bias subtraction proceeds exactly as performed during ground calibration testing, with the bias removal achieved by simple subtraction of the bias image from the science image. There are several drawbacks to this approach: (1) more images must be taken, which affects the data volume that must be stored on the on-board solid-state recorder, (2) more data must be downlinked, which may not be possible because of limited downlink bandwidth and/or the cost associated with the extra Deep Space Network (DSN) support required, (3) the signal-to-noise ratio (SNR) may be degraded because the bias subtraction no longer involves a high SNR reference file, and (4) fewer science images can be obtained because they have been displaced in the observing timeline by extra bias images. 9.3.1.2 Smear Removal LORRI does not have a shutter, so the target being observed illuminates the active region of the CCD whenever LORRI is pointed at the scene. In particular, the CCD continues to record the scene as the charge is transferred from the active portion to the storage area, and this results in a smearing of the observed scene. Fortunately, this smear can be removed to high accuracy using the correction algorithm described below. When bright objects are observed, the readout smear makes the raw image difficult to use for analysis purposes. In the image of Jupiter below, the raw image is on the left and the calibrated image with readout smear (aka frame transfer smear) removed is on the right.

Figure 9-8: Demonstration of Smear Removal

The need for the readout smear removal arises from the operation of

the frame transfer CCD used in LORRI, where first the image zone is

flushed, then an exposure is taken, and finally the image is

transferred into the storage zone. Hence a pixel of the raw image is

exposed to the scene radiance from the corresponding geometrical

element of the scene, but it is also exposed to the radiances of all

the scene elements in the same image column during the image

transfers. Thus the raw image is the superposition of the scene

radiance and the signal acquired during frame transfers, which is

called readout smear.

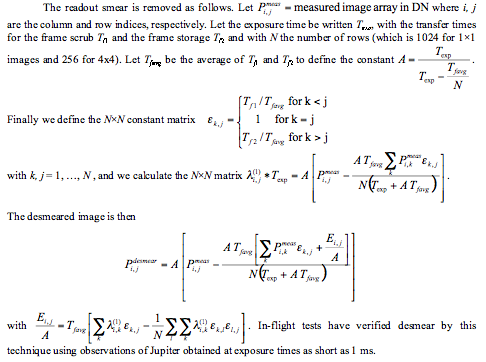

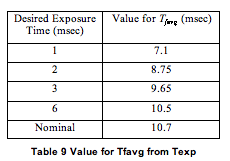

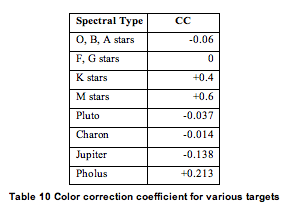

The readout smear is removed as follows.

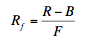

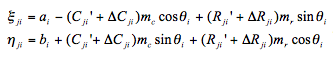

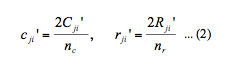

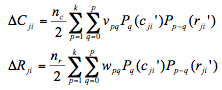

Equation 9-1

Figure 9-8: Demonstration of Smear Removal

The need for the readout smear removal arises from the operation of

the frame transfer CCD used in LORRI, where first the image zone is

flushed, then an exposure is taken, and finally the image is

transferred into the storage zone. Hence a pixel of the raw image is

exposed to the scene radiance from the corresponding geometrical